- #MONTE CARLO SIMULATION SOFTWARE FREE DOWNLOAD TRIAL#

- #MONTE CARLO SIMULATION SOFTWARE FREE DOWNLOAD PLUS#

We discuss recent advances in all these areas and outline interesting future directions. These include the use of Monte Carlo in addressing polymer self-assembly, structure and conformation in polymer nanocomposites, polymers under flow, confined polymers, grafted polymers, polymer rings and knots, semiflexible polymers, polymer networks, polymer crystallization, and polymerization reactions.

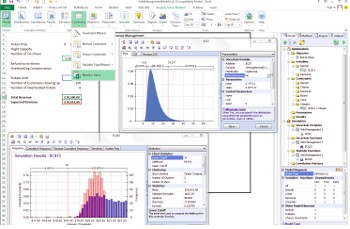

We start by presenting the basic concepts underlying the method, then we review progress in the development of new Monte Carlo moves or interesting implementations of existing moves to new systems, then we discuss the development of new software for the more friendly execution of Monte Carlo simulations, and finally we discuss findings from several applications to polymer systems.

Our goal in this rather short report is to highlight important advances over the last 10 years or so, with some more emphasis on new applications to complex systems. In the last years, the method has expanded considerably through numerous applications in a variety of systems, often in the form of hybrid schemes with theoretic methods, thus providing invaluable insight into their thermodynamic, structural and conformational properties (and indirectly the dynamic ones). This is especially important at low temperatures or for systems characterized by highly dense structures, since dynamics becomes too slow to be followed reliably and ergodically by a detailed dynamic method. Combined, in particular, with methods such as replica exchange, these moves can accelerate system equilibration by several orders of magnitude compared to dynamic methods such as Molecular Dynamics (MD).

#MONTE CARLO SIMULATION SOFTWARE FREE DOWNLOAD TRIAL#

It is particularly suited for simulating the bulk phases of chain-like (polymer or macromolecular) systems, because one can think of several such moves (both simple and complex) and combinations thereof that can design in order to generate trial states. Metropolis Monte Carlo is a powerful simulation technique for equilibrating the dense phases of complex systems and predicting their key physicochemical properties because of the freedom it provides to sample new points in phase space thanks to the design of artificial (even fictitious) trial moves that can take the system completely away from its natural trajectory.

#MONTE CARLO SIMULATION SOFTWARE FREE DOWNLOAD PLUS#

We also include a short section discussing some key remaining challenges plus interesting future opportunities. We highlight, in particular, extensions of the method to non-equilibrium systems (e.g., polymers under steady shear flow) guided by non-equilibrium thermodynamics and emphasize the importance of hybrid modeling schemes (e.g., coupled Monte Carlo simulations with field theoretic calculations). In this short review, we highlight recent progress in the field (with a clear emphasis in the last 10 years or so) by presenting examples from applications of the method to several systems in Soft Matter, such as polymer nanocomposites, soft nanostructured materials, confined polymers, polymer rings and knots, hydrogels and networks, crystalline polymers, and many others. In the last years, Monte Carlo has advanced considerably thanks to the design of new moves or to the efficient implementation of existing ones to considerably more complex systems than those for which these were originally proposed. Owing, in particular, to the freedom it provides to accelerate sampling in phase space through the clever design and proper implementation of even unphysical moves that take the system completely away from its natural trajectory, and despite that it cannot provide any direct information about dynamics, it has turned to a powerful simulation tool today, often viewed as an excellent alternative to the other, most popular method of Molecular Dynamics. Metropolis Monte Carlo has been employed with remarkable success over the years to simulate the dense phases of polymer systems.

3Particle Technology Laboratory, Department of Mechanical and Process Engineering, ETH Zürich, Zürich, Switzerland.2Institute of Chemical Engineering Sciences (ICE-HT), Foundation for Research and Technology, Hellas (FORTH), Patras, Greece.1Department of Chemical Engineering, University of Patras, Patras, Greece.

0 kommentar(er)

0 kommentar(er)